The Medical Industry

The Medical Industry

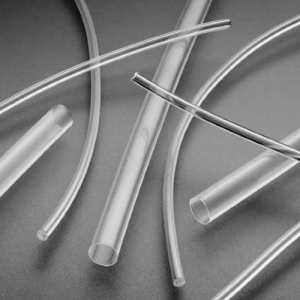

Medical technologies have revolutionized the healthcare system – there are new systems, new treatments, new tools, and new devices that come to market that change the way we receive treatment. One tool, however, is a vital accessory that has stood the test of time – medical-grade heat shrink tubing. Medical-grade heat shrink tubing offers abrasion protection in medical instruments, insulation in laparoscopic electrosurgical devices, mechanical protection and insulation of highly flexible joints, and as a processing aid for interventional applications.

The demand for less-invasive medical procedures is a major driving force in today’s medical device industry. Smaller and thinner are better—especially in catheters, endoscopes, and other devices that are inserted into the body. Designers are looking for new ways to downsize existing devices and to develop new minimally invasive devices. The industry is also under pressure to build more features into devices without increasing their profile (size). Thin-wall heat shrink tubing is one product that can help designers meet this demand by reducing diameters and improving production processes.

Types

All medical-grade heat shrink tubing is extruded from polyolefin and fluoropolymers. Each type has a variety of uses, applications, and obligations they fulfill.

Polyolefin is a synthetic polymer commonly found in many consumer plastics, such as plastic bottles, bottle caps, liquid containers, and tubing.

Fluoropolymer is a carbon-based polymer used for non-stick plastics and is highly resistant to solvents, acids, and bases.

Benefits and Features

Medical grade heat shrink tubing is perfectly suited for a wide variety of medical applications. Features include:

• Semi-rigid with a higher shrink temperature and heat resistance, creating a smooth finish on the surface after the heat shrink tubing is removed.

• Extraordinary mechanical endurance best for stiffening, electrical insulation, strain relief, and aiding in the demands of the medical environment.

• Good surface lubricity with extremely thin expandable walls and elevated compressive strength.

• Resistant to chemicals such as hexachlorophene, povidone-iodine, alcohol, benzalkonium, and saline solutions, as well as fungus and moisture.

• 2:1 ratio and meets all USP Class IV bio-compatible requirements.

• Available in blue, black, white, or clear.

• Size options include 1/2”, 3/16”, 3/32”, 1/8”, 1/4” and 3/8”

Contact Nu-Tech today for a professional opinion on medical heat shrink tubing. We’ll answer any question and get you sorted in no time.