Micro Welding Services

Micro Welding Services

Nu-Tech provides micro precision TIG welding services. This process can be used in multiple applications within aerospace, medical, laboratory, and commercial projects. With many years of experience, our team is capable of running prototypes to production quantities for your company.

We possess the knowledge and expertise to perform the most microscopic welds using our Micro TIG Welding Services. We have a fully equipped welding lab dedicated to micro-weld production and design modifications.

What is Micro TIG Welding?

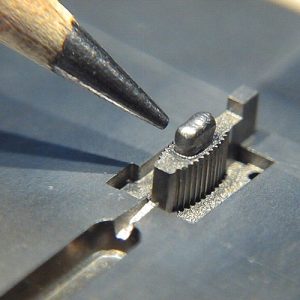

Micro TIG welding is a very precisely controlled welding process for welding parts that cannot be welded with normal TIG welding due to heat input and warping. As the name implies, it is performed under a microscope. In micro TIG welding, specialized power supplies are used due to their ability to go down to 1/10 of an amp with a stable arc. Micro TIG welding also utilizes filler wires ranging from .005 inches to .035 inches. Intricate welds can be performed with this process while depositing very precise amounts of weld material. Weld buildups can be as small as .005 inches.

Micro TIG Welding Applications

Micro-weld repair can be used in a variety of applications. A popular use for Micro TIG welding is the repair of detailed features on plastic injection and die-cast molds. Other applications include:

• Commercial projects

• Intricate fabrications and assemblies

• Connectors and electronic devices

• Firearm welding

• Medical devices

• Tool assemblies

• Electronics

• Dental

• Miniature assemblies

Due to the lower heat input, micro TIG welding introduces less stress into the part. This is useful for many applications which produce delicate or intricately engineered parts. Likewise, micro TIG welding is the process of choice when an engineering change is in order. Changes in shapes, sizes, and geometries can be made in a time-saving and cost-efficient manner compared to inserting or remaking an entire cavity or die section. Be warned, a TIG-weld puddle (regardless of the size) heats up to a couple of thousand degrees Fahrenheit, which can cause distortion and damage to small molds and inserts during welding.

Experience is the most critical component to micro-TIG welding success. It is very difficult to become a proficient micro-TIG welder with no welding background because the operator has to learn the basic steps, such as starting an arc before he or she can progress. One becomes a micro-TIG welder by becoming a proficient TIG welder first then moving to a special mold-welding microscope for practice. However, learning to weld under a microscope takes time, as the welder gradually learns about the depth of field and positioning. Consultants are available who can help train already-established TIG welders in the fundamentals of micro-TIG welding.

Micro TIG Welding Advantages

• Achieve a deeper penetration

• Reach difficult areas

• Durable and discrete welds

• Lower cost than remaking the damaged part

• Faster and less expensive than laser welding

• Welds as small as .010 mean less machining is needed.