Microscopic TIG Welding in Mold & Die Repair

Microscopic TIG Welding in Mold & Die Repair

Introduction

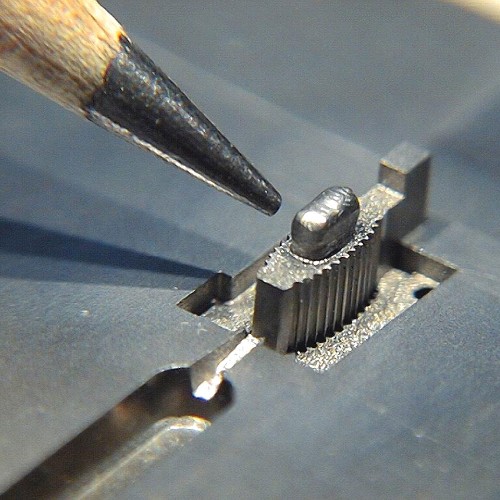

Molds and dies are some of the most expensive and highly used assets in manufacturing. Over time, even the best tools develop wear: small chips, edge erosion, micro-cracks, and surface imperfections. Instead of replacing entire tools, many manufacturers now rely on microscopic TIG welding to restore precision details and extend mold life. This ultra-fine welding process is built for accuracy at the microscopic scale, making it ideal for repairing complex, high-value tooling.

1. Why Molds and Dies Need Microscopic Precision

Modern molds often include:

-

Intricate geometries

-

Sharp corners and micro-features

-

Thin edges or vent details

-

High-precision surfaces

When these areas wear down, repairs must be extremely targeted. Broad heat input or excessive material can distort the tool or require unnecessary re-machining.

Microscopic TIG welding offers controlled, pinpoint metal addition that supports detailed features without affecting the surrounding material.

2. Benefits of Micro-TIG Welding for Tooling Repair

✓ Ultra-Localized Heat

Only a tiny area receives heat, which helps maintain:

-

Dimensional accuracy

-

Surface flatness

-

Material integrity

This is especially important for molds that must adhere to tight tolerances.

✓ Precise Metal Placement

Microscopic TIG welding allows small, controlled deposits ideal for:

-

Tight cavity corners

-

Thin edges

-

Micro ribs and detail lines

-

Undercut features

Manufacturers can rebuild only what’s damaged instead of removing large areas.

✓ Extended Mold & Die Lifespan

Because the process is targeted and gentle on surrounding features, molds can be:

-

Repaired multiple times

-

Maintained without full replacement

-

Restored quickly to production-ready condition

This reduces downtime and maximizes return on tooling investments.

✓ Compatible With High-Performance Tool Steels

Many molds are made from:

-

H13

-

D2

-

Stainless tool steels

-

Hardened alloys

Microscopic TIG welding supports extremely fine work on these materials, restoring edges or surfaces with accuracy.

3. Common Mold & Die Repairs Done With Micro-TIG

Edge Buildups

Thin edges and parting lines wear down quickly. Micro-TIG allows manufacturers to rebuild them without altering nearby geometry.

Detail Reconstruction

Small logos, textures, tiny channels, and micro-features can be restored without re-cutting the entire mold cavity.

Surface Defect Correction

Minor defects such as nicks, pits, or small cracks can be filled or reinforced with tiny weld additions.

Gate & Vent Area Touch-Ups

Injection molds often suffer from erosion in gate regions. Microscopic TIG allows precise restoration that keeps flow characteristics intact.

Emergency Repair Work

When a mold is damaged mid-production, quick, localized repair minimizes downtime and avoids full rebuilds.

4. Where Micro-TIG Fits in the Repair Workflow

Microscopic TIG welding usually appears after inspection and before re-machining or polishing. It’s part of a streamlined tooling maintenance workflow:

-

Assessment of worn or damaged areas

-

Microscopic TIG metal addition to rebuild precise features

-

Final machining or polishing to return the mold to spec

Because the welds are so small and controlled, finishing steps often require less effort, helping manufacturers return to production faster.

5. Why Manufacturers Prefer It Over Alternatives

Compared to broader welding or full-tool replacement, micro-TIG welding provides:

-

Fewer thermal stresses

-

Less rework after welding

-

Lower repair cost

-

Faster turnaround

-

Longer tool service life

For molds and dies used in automotive, plastics, medical devices, and consumer goods, this precision repair method has become essential.

Conclusion

Microscopic TIG welding has become a cornerstone of modern mold and die repair because it delivers high-precision restoration, minimal thermal impact, and significant cost savings. It empowers manufacturers to maintain detailed tooling, extend mold life, and keep production running smoothly—making it an essential capability in high-precision industries today.