In high-precision industries, traditional welding methods often fall short. When working with miniature components or ultra-thin materials, you need a process that delivers pinpoint accuracy and maximum control. That’s why at Nu-Tech, we specialize in micro TIG welding—a method designed specifically for applications where every micron matters.

In high-precision industries, traditional welding methods often fall short. When working with miniature components or ultra-thin materials, you need a process that delivers pinpoint accuracy and maximum control. That’s why at Nu-Tech, we specialize in micro TIG welding—a method designed specifically for applications where every micron matters.

What Is Micro TIG Welding?

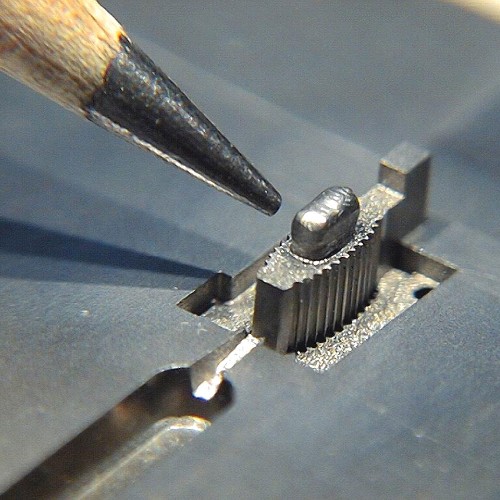

Micro TIG (Tungsten Inert Gas) welding is a highly controlled version of conventional TIG welding, operating at very low amperages (as low as 0.1 amps) with precise torch movement and arc stability. It’s used to join very small, delicate, or high-value components where distortion, overheating, or contamination cannot be tolerated.

Why We Use It

1. Extreme Precision

Micro TIG allows for welds that are just fractions of a millimeter wide, making it ideal for industries like aerospace, medical devices, electronics, and nuclear systems. At Nu-Tech, we use high-magnification microscopes and CNC torch controls to ensure flawless accuracy.

2. Superior Weld Quality

Thanks to a clean, stable arc and ultra-pure shielding gas, micro TIG produces welds that are strong, consistent, and free of contamination. This is essential in mission-critical applications, where even a minor flaw can lead to failure.

3. Low Heat Input

Micro TIG’s low amperage keeps heat-affected zones (HAZ) to a minimum, reducing the risk of warping or damage to sensitive components. It’s especially beneficial when welding thin metals or dissimilar alloys that respond poorly to excessive heat.

4. Repeatability and Control

With programmable pulse settings and finely tuned parameters, Nu-Tech can replicate identical welds across large production runs. This repeatability is key in regulated industries that demand strict quality standards.

5. Versatility

From titanium and stainless steel to cobalt-chrome and exotic alloys, micro TIG works on a wide range of materials. Whether we’re welding implant-grade medical components or miniature aerospace sensors, it adapts to the task.

Precision Is Our Standard

At Nu-Tech, micro TIG welding isn’t just a specialty—it’s our standard. Our team has decades of experience handling the world’s most demanding welding applications with unmatched consistency and care.

If your project calls for high-precision welds with zero margin for error, Nu-Tech is ready to help.

Contact us today to learn how micro TIG welding can elevate your components and your business.