Heat shrink tubing is one of the most adaptable and underrated tools in electrical and mechanical work. Originally developed for insulating wires, this simple yet highly effective product has evolved to serve countless functions across industries—from aerospace to home DIY. Its ability to insulate, seal, protect, and organize makes heat shrink tubing an essential component for professionals and hobbyists alike.

Heat shrink tubing is one of the most adaptable and underrated tools in electrical and mechanical work. Originally developed for insulating wires, this simple yet highly effective product has evolved to serve countless functions across industries—from aerospace to home DIY. Its ability to insulate, seal, protect, and organize makes heat shrink tubing an essential component for professionals and hobbyists alike.

Protection for Wires and Cables

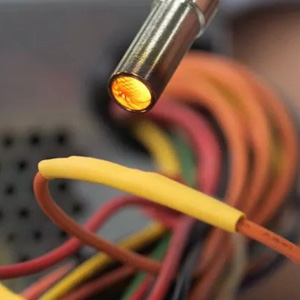

At its core, heat shrink tubing provides insulation and protection for wires and cables. When heated, the tubing shrinks to form a tight, secure covering that guards against moisture, dust, chemicals, and mechanical wear. This makes it ideal for applications where wires are exposed to harsh conditions or require long-term reliability.

Color Coding and Organization

Heat shrink tubing isn’t just functional—it also helps with visual organization. Available in a wide range of colors, it can be used to label or differentiate cables, circuits, and connectors. In complex electrical systems, this makes troubleshooting faster and prevents wiring errors. Some heat shrink options even support custom printing or barcoding for large-scale projects.

Mechanical Reinforcement

In addition to its insulating properties, heat shrink can provide mechanical reinforcement to splices and joints. By tightly binding components, it adds an extra layer of strain relief that helps prevent cables from bending, fraying, or breaking at connection points. This is especially useful in automotive or industrial settings where vibration and movement are common.

Sealing and Waterproofing

Certain types of heat shrink tubing include adhesive linings that melt and flow when heated, creating a watertight seal around the enclosed components. This capability is particularly valuable in marine environments, underground wiring, or any place where moisture protection is critical. It’s a simple, effective solution that doesn’t require specialized sealing equipment.

Adaptability Across Materials and Shapes

One of the most impressive aspects of heat shrink tubing is its ability to conform to irregular shapes and a wide variety of materials. Whether you’re bundling multiple wires, covering a soldered joint, or protecting delicate sensors, heat shrink molds itself to the object’s surface for a snug fit. This flexibility makes it suitable for applications ranging from circuit boards to tool handles.

Beyond Electronics: Creative Uses

Heat shrink tubing isn’t limited to electrical work. It’s often used in crafts, tool grips, fishing rod repairs, and even in the medical field to bundle tubing or reinforce delicate instruments. Its clean finish, customizable length, and variety of diameters make it a handy material for creative problem-solving wherever secure wrapping is needed.

Few products offer the kind of utility and adaptability that heat shrink tubing does. Its ability to insulate, protect, seal, organize, and reinforce makes it invaluable across countless industries and use cases. Whether you’re an electrician, engineer, mechanic, or maker, heat shrink tubing is a smart, flexible solution that can simplify your work and strengthen your results.