Learn how to select the right heat shrink tubing for your industry. Discover tips on materials, shrink ratios, and environmental considerations for reliable electrical protection and cable management.

Learn how to select the right heat shrink tubing for your industry. Discover tips on materials, shrink ratios, and environmental considerations for reliable electrical protection and cable management.

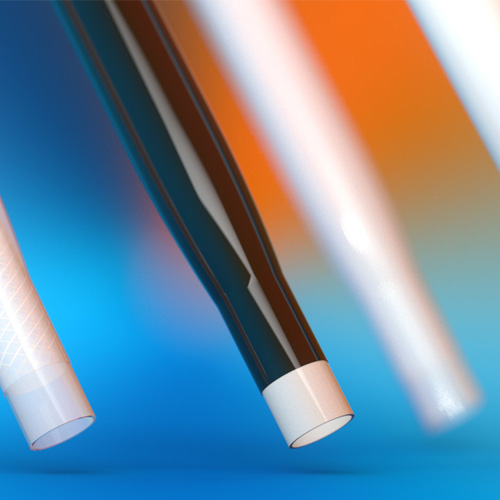

What Is Heat Shrink Tubing?

Heat shrink tubing is a polymer sleeve that contracts when exposed to heat, providing a secure protective layer over wires, cables, and connectors. It is widely used in industries such as automotive, aerospace, telecommunications, and industrial manufacturing for insulation, strain relief, and environmental protection.

Choosing the right heat shrink tubing is essential to ensure safety, durability, and optimal performance.

Step 1: Identify Your Application Environment

The first step in selecting the right heat shrink tubing is understanding the conditions your cables will face. Consider the following:

-

Temperature range: High-temperature environments may require PTFE or silicone tubing.

-

Chemical exposure: Industrial chemicals, oils, and solvents can degrade certain materials.

-

Outdoor vs. indoor use: UV resistance and moisture sealing are crucial for outdoor installations.

-

Mechanical stress: Vibrations or frequent handling may require reinforced or adhesive-lined tubing.

Selecting tubing suited for the environment ensures long-lasting protection and reduces maintenance costs.

Step 2: Determine the Required Shrink Ratio

The shrink ratio indicates how much the tubing will contract when heated. Common ratios include:

-

2:1 ratio: Shrinks to half its original diameter; ideal for standard wire insulation.

-

3:1 or 4:1 ratio: Provides extra flexibility for irregular shapes or connectors.

Measure the largest and smallest diameters of your wires or components to select the correct shrink ratio for a tight, secure fit.

Step 3: Choose the Correct Material

Different industries and applications require specific tubing materials:

-

Polyolefin: Most common; flexible, durable, and cost-effective.

-

PVC: Economical; suitable for low-temperature applications.

-

PTFE / Fluoropolymers: Chemical- and temperature-resistant for harsh environments.

-

Silicone: Highly flexible, ideal for high-temperature or vibration-prone areas.

Selecting the right material ensures reliable insulation, chemical resistance, and mechanical protection.

Step 4: Consider Adhesive-Lined Tubing

Adhesive-lined heat shrink tubing melts internally during installation, creating a moisture-tight seal. Benefits include:

-

Protection against corrosion

-

Environmental sealing for outdoor or marine applications

-

Enhanced strain relief

Adhesive-lined tubing is ideal for applications exposed to moisture, chemicals, or harsh conditions.

Step 5: Check Compliance and Industry Standards

Many industries require tubing that meets specific safety and performance standards, such as:

-

UL-listed (Underwriters Laboratories)

-

MIL-SPEC (Military Specifications)

-

SAE standards (Automotive Industry)

Using compliant heat shrink tubing ensures regulatory compliance and enhances safety in critical applications.

Why Nu-Tech Is Your Go-To Supplier in North Carolina

At Nu-Tech, we provide high-quality heat shrink tubing for every industry, from automotive wiring harnesses to aerospace and industrial applications. Our products meet UL, MIL-SPEC, and SAE standards, guaranteeing safety, reliability, and durability for your electrical and cable management needs.

Selecting the right heat shrink tubing requires careful consideration of environment, shrink ratio, material, and standards. Choosing the right product protects your wiring, extends equipment life, and ensures compliance with industry requirements.