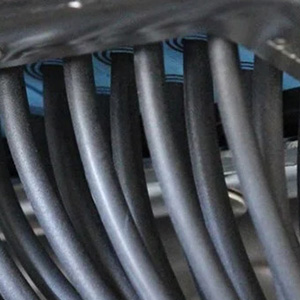

Heat shrink tubing is a popular and effective way to provide electrical insulation for wires, cables, and connections. Whether you’re repairing a damaged wire or building an electronic project from scratch, this simple tubing plays a big role in keeping electrical systems safe and reliable.

Heat shrink tubing is a popular and effective way to provide electrical insulation for wires, cables, and connections. Whether you’re repairing a damaged wire or building an electronic project from scratch, this simple tubing plays a big role in keeping electrical systems safe and reliable.

What Is Electrical Insulation?

Electrical insulation is a protective layer that prevents electrical currents from coming into contact with other conductors or surfaces. Without proper insulation, wires can short circuit, cause sparks, or even start fires. Insulating materials help control the flow of electricity and protect users from shocks or injuries.

How Heat Shrink Tubing Works as an Insulator

Heat shrink tubing is made from plastic materials like polyolefin that do not conduct electricity. When heated, the tubing shrinks tightly around wires or connections, forming a secure, non-conductive barrier. This barrier prevents exposed metal from touching other wires or surfaces, reducing the risk of shorts or electric shock.

The tight fit also helps keep the insulation in place, even in harsh environments where wires may be subject to movement, vibration, or moisture.

Why It’s a Great Choice

Here are a few reasons heat shrink tubing is widely used for electrical insulation:

-

Easy to Use: Just slide it over the exposed wire and apply heat.

-

Durable: It resists wear, chemicals, and environmental damage.

-

Reliable: It forms a tight seal that won’t easily loosen or fall off.

-

Versatile: Comes in many sizes and colors for different wire types and uses.

Common Applications

-

Repairing damaged wire insulation

-

Insulating soldered wire joints

-

Protecting connectors and terminals

-

Sealing splices in automotive or marine wiring

Final Thoughts

Heat shrink tubing is a simple, affordable, and highly effective solution for electrical insulation. It adds a layer of safety and protection that helps your electrical work last longer and perform better. Whether you’re working on home repairs or professional installations, heat shrink tubing is an essential tool for clean, safe wiring.